Brushless Resolvers for Harsh Environment Applications

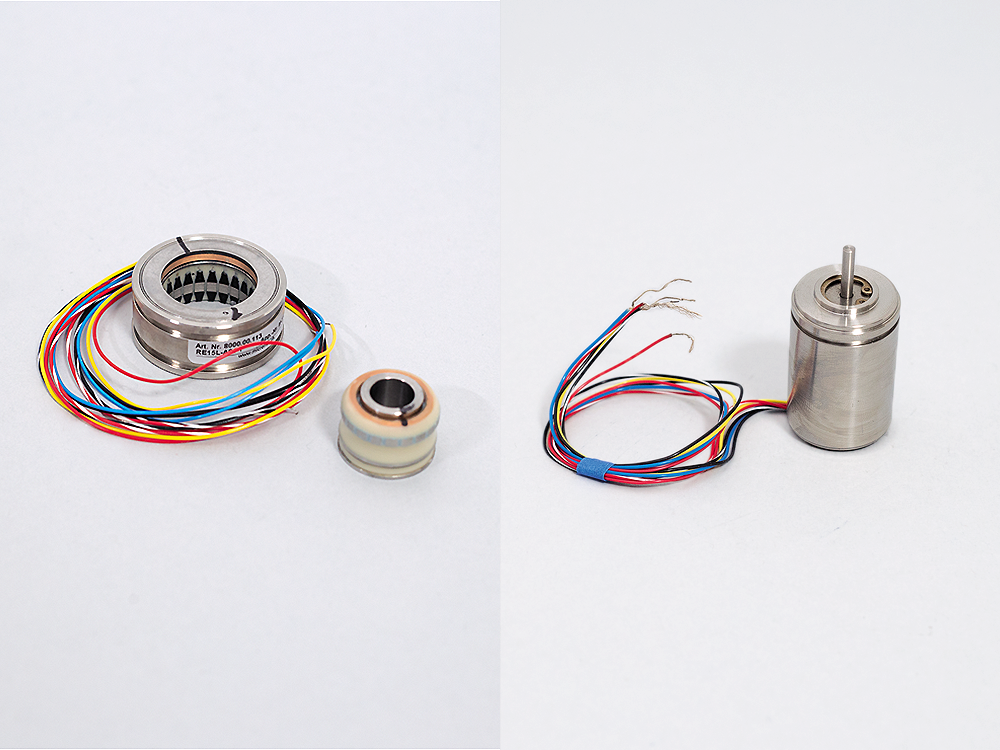

Brushless Resolvers in both Pancake (Size 20mm to 75mm) and Size 11 (28mm OD) Shaft configurations

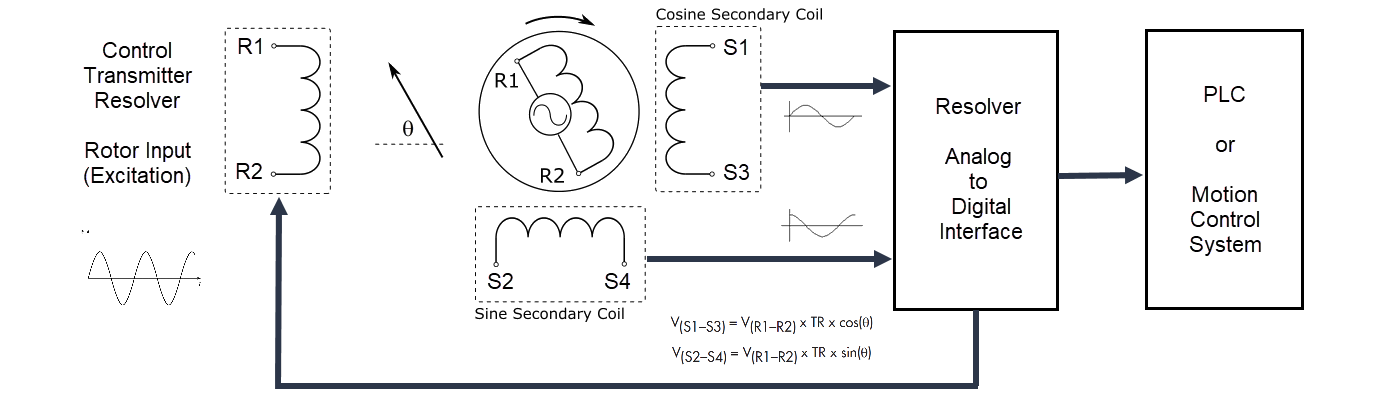

Resolvers are absolute analog rotary encoders which are ideal for harsh environments. Unlike conventional optical or magnetic rotary encoder (with internal temperature-limiting electronics), the resolver is similar to a transformer in construction and does not incorporate any electronics. An external R/D (resolver-to-digital) interface is required which is also why the resolver can withstand extreme environments (-55°C to +155°C for frame-less resolvers).

There are two types of resolvers: Control Transmitter and Control Transformer. The Control Transmitter features single excitation input to rotor input and sine/cosine stator outputs. The Control Transformer resolver requires both sine/cosine reference stator inputs and rotor output is a phase-shifted sine signal.

For new designs, the control transmitter type resolver is recommended as commercial R/D interfaces are available from many manufacturers. For board level designs, R/D conversion ICs are available from Analog Devices and Texas Instruments.

Looking for Size 11 Shafted Resolver?

R11 series is Size 11 (1.1`-inch OD) brushless resolvers with ∅0.120-in shaft. Operating temperature is -40°C to +125°C. For new applications requiring a shafted resolver, the controller transmitter R11XJ107 is recommended. A radiation resistant version R11XJ107N is also available.

Replacements for Thomson Micron and Neotech internal resolvers are also available. See R11 series.

Looking for Brushless, Frameless Resolver of a certain size?

REXXXX series represent a range of brushless, frameless resolvers for embedded applications and direct integration into motors and other robotic mechanisms. These resolvers have a unique magnetically-shaped solid rotor, meaning the rotor is solid metal with no internal winding. These resolvers are ideal for harsh environments with high shock and vibration. High temperature models are also radiation resistant. All of the following are available in Standard Temperature (-40°C to +135°C) or High Temperature (-70°C to +200°C), also radiation resistant), and Standard Speed or High Speed.

- RE2010, Size 08 (0.8″ or 20mm OD) with 4mm bore, maximum 160’000 rpm

- RE3620, Size 15 (1.5″ or 36mm OD) with 10mm bore, maximum 110’000 rpm

- RE5032, Size 21 (2.1″ or 50mm OD) with 20mm bore, maximum 65’000 rpm

- Special RE6040 available (60mm OD) with 26mm bore, maximum 35’000 rpm

- RE7557, Size 30 (3.0″ or 750mm OD) with 46mm bore, maximum 28’000 rpm

- Standard gap is 0.3″, special 1mm gap available

- Special bore sizes available

- Special mounting features available (i.e. flange)

- Contact Micronor Sales with your special requirements

Electromechanical Absolute and Incremental Encoders

Featuring ABSOLUTE ENCODERS with SSI or Analog Position Outputs and INCREMENTAL ENCODERS with A/B/Z Quadrature Outputs

Are you looking for an Absolute or Incremental Encoder? What is the difference?

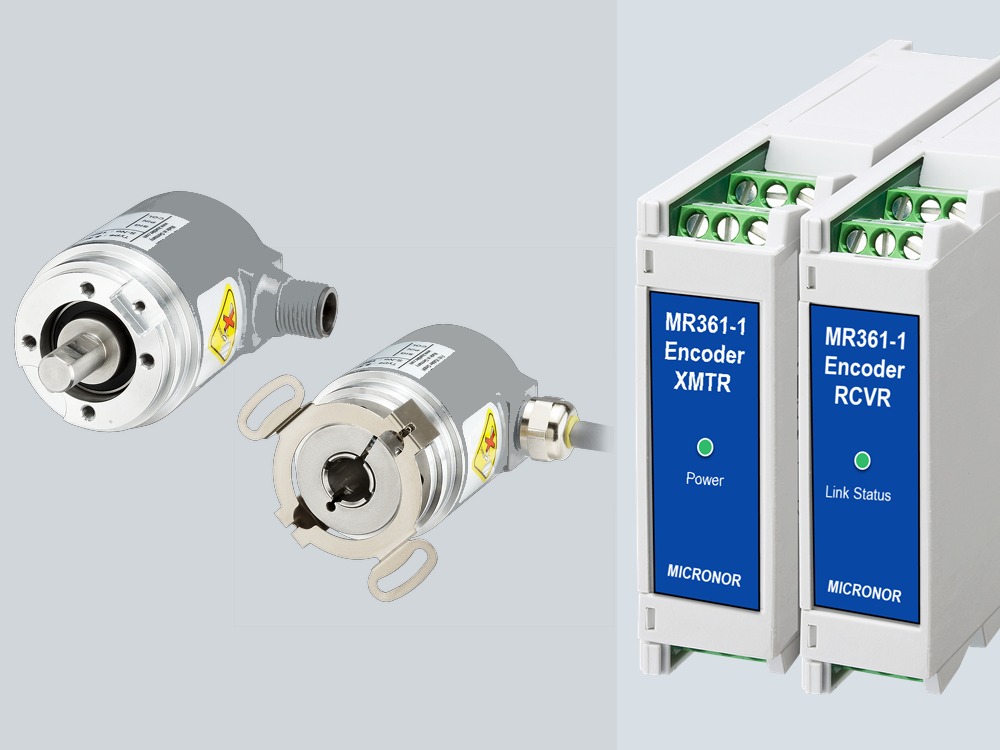

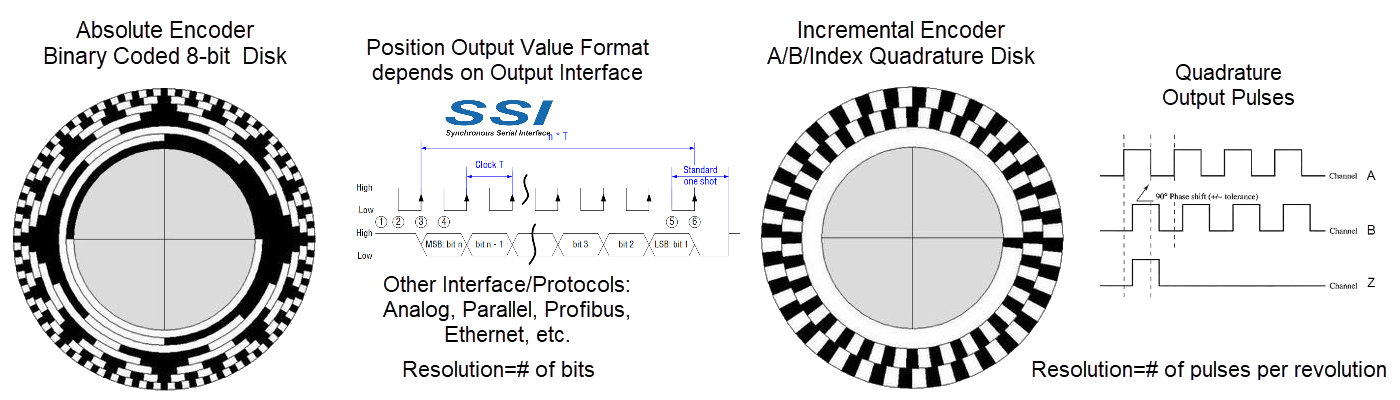

- Absolute encoders (also called position sensors) are used where monitoring absolute position and high precision are required. There are two types: single turn (output monitored over one revolution, 0-360 degrees) and multiturn (provides single turn position and tracks # of turns up to 65,536 revolutions. Their signature output is a digital value of absolute position via any number of interface options – SSI, Analog, Profibus, CANopen, Ethernet, etc. SSI (synchronous serial interface) is considered the native, most robust absolute encoder interface option. if an absolute encoder loses power and even if shaft turned during outage, it will always report the current position upon start-up. This section describes our conventional Electromechanical Absolute Encoders (i.e. electronics based) as Fiber Optic Absolute Encoders (where immunity to interference, emi/rfi, rf, microwaves, magnetic fields, electrical fields, radiation, or long distance operation is required).

- Incremental encoders are used where speed and relative position need to be monitored. Their signature outputs are A/B/Index quadrature pulses. The user’s motion control system tracks these pulses (phasing determines direction) to monitor relative position from initial Home setting. By measuring the time between pulses, the same system can track speed. If the system loses power, all position and speed information is typically lost. This section describes our conventional Electromechanical Incremental Encoders (electronics-based, typically optical or magnetic) as well as Fiber Optic Incremental Encoders (where immunity to interference, emi/rfi, rf, microwaves, magnetic fields, electrical fields, radiation, or long distance operation is required).

- Fiber Optic Encoder Extenders can extend the operating distance of conventional Electromechanical encoders but choose the right model that matches your encoder type – MR361-1 for incremental encoders and MR361-2 for absolute encoders.

Looking for Absolute Encoder with 4-20mA or 0-10V analog output?

Go to Absolute Encoder product page.

Looking for Absolute Encoder with SSI output?

Go to Absolute Encoder product page.

Looking for Incremental Encoder with A/B/Z quadrature outputs?

Go to Incremental Encoder product page.

Looking for Draw Wire Linear Encoder, either to monitor Absolute Position or Incremental Position/Speed?

If application requires Absolute or Incremental Encoder for monitoring linear travel from 1.5m-50m, then go to Draw Wire Encoders product page.

Looking for Measuring Wheel Encoder System, either to monitor Absolute Position or Incremental Position/Speed?

If application requires Absolute or Incremental Encoder to monitor linear travel with a measuring wheel, then go to Measuring Wheels product page.