| Date of Presentation | Title | Download SLIDES Link |

|

Wed, June 25 2025 1:30pm LIVE Theater on the Show Floor |

Fiber Optic Sensors are displacing their Electrical Counterparts in Critical Applications | Download SC2025 LIVE FO Sensor Presentation |

| Every Hour At the Booth |

10-minute Fiber Optic Sensors microTour featuring:

|

Download SC2025 Fiber Optic Sensor Brochure |

| For Your Reference | Everything You Need To Know About Fiber Optic Sensors (Seminar presented at San Diego/Del Mar Electronics Show, April 2024) | Download THE BIG DMEMS FO Sensor Presentation |

The Fiber Optic BUZZ will be at Sensors Converge 2025

Micronor Sensors Booth #829 features Interactive Demonstrations of FO Temperature, Position, Signaling, and Strain Sensors

We are the only sensor solutions provider where fiber optic and electromechanical sensor technology solutions converge from one very experienced source

Sensors are very broad class of components. Our focus is solely on sensors for kinetic applications, where things are in motion or put into motion. Many of our most popular fiber optic products are available off-the-shelf – such as the FO Emergency Stop, FO Microswitch, FOTEMP temperature probes as well as Fiber Bragg Grating interrogators and some stock FBG strain and temperature sensor chains.

Here are some of our most exciting products:

- FOTEMP (GaAs) Fiber Optic Temperature Sensors and Signal Conditioners provide high accuracy (+/-0.2K) over measurement range of -200°C to +300°C.

- BRAGG (FBG) Temperature Sensors and Interrogators where single and multipoint temperature measurement is required and require a measurement range of -250°C to +800°C. required.

- Lilikoi Femto Optica Force Sensors for robotic applications where electromagnet immunity and more is required. Products include miniature Fiber Optic Load Cell, gripper and grasper sensors.

- Micronor MR660 Multiaxis Fiber Optic Acceleration/Vibration Sensor system which can measure up to 50g’s.

- Micronor MR387 series Fiber Optic Emergency Stop sensor system which can operate up to 10km

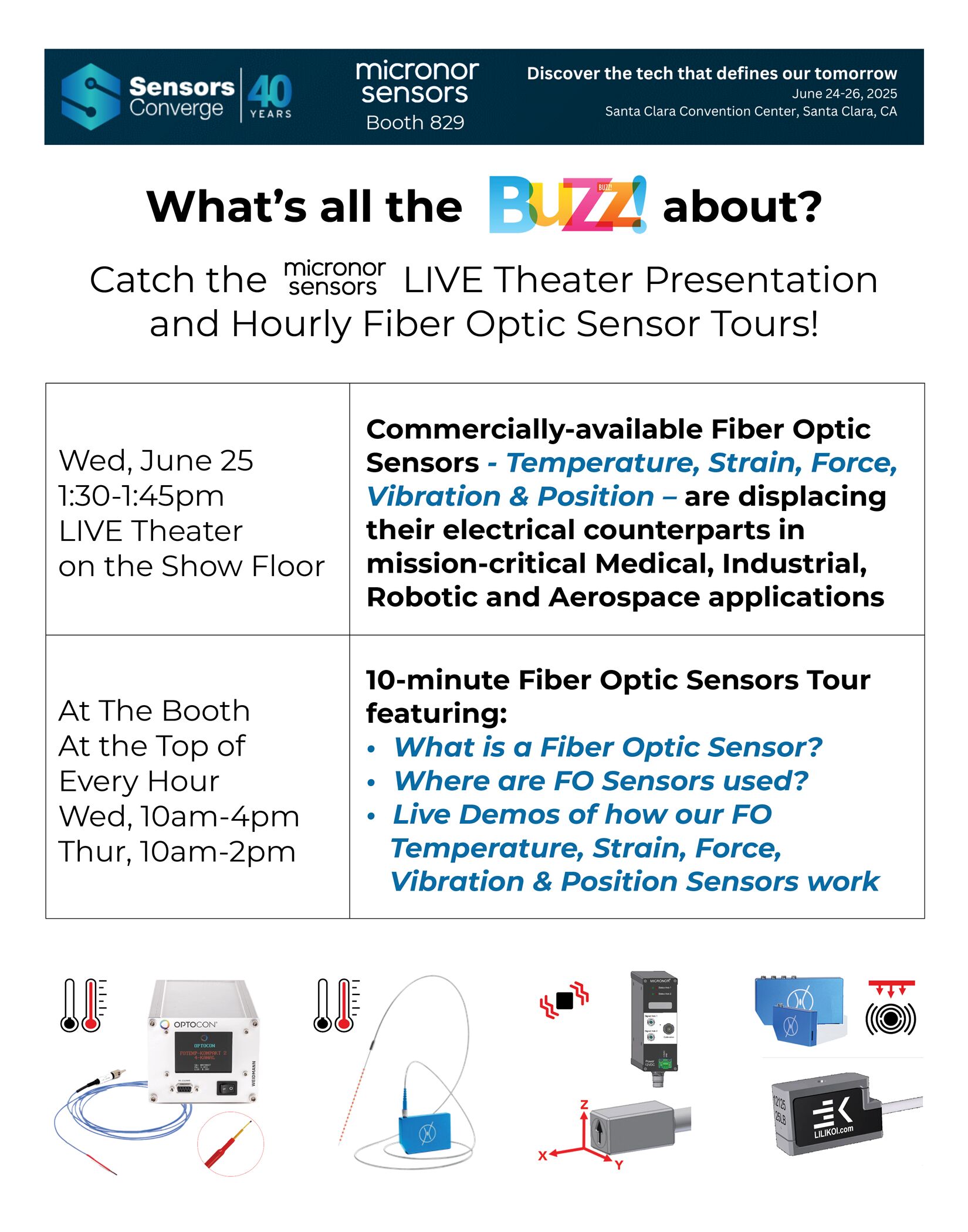

- Micronor MR386 series Fiber Optic Microswitch/Limit Switch where physical discrete position signally is required. Same form factor as a Omron or Honeywell V-series microswitch.

- Micronor MR430 Fiber Optic Absolute Rotary Encoder Systems and MR340 series FO Incremental Rotary Encoder Systems for MRI and other harsh environment robotic applications where a non-metallic sensor which is immune to EMI, RFI, magnetic, RF and electric fields is required.

WHEN DO I NEED A FIBER OPTIC SENSOR?

Fiber Optic Sensors are for operating environments where electromagnetic immunity is required and electronics-based sensors are hazardous or unreliable. These applications typically require immunity to emi/rfi, magnetic fields, electric fields, plasma fields, RF environments, microwave ovens, high voltage, radiation, and extended distances.

Micronor specializes in fiber optic kinetic sensors for feedback in mechanical motion applications where immunity to interference, voltage, RF, microwaves, magnetic fields, and/or radiation is required:

• TEMPERATURE, Fiber optic thermometers for industry, medical, research and OEM

• FORCE, Fiber optic force sensors for robotic applications

• POSITION, absolute rotary and linear sensors

• MOTION, incremental rotary and linear sensors

• SIGNALING & SECURITY, E-Stop, microswitch, key switch, pushbutton and manhole sensor

• ACCELERATION, Multiaxis acceleration sensors for real-time vibration analysis

• TEMPERATURE AND STRAIN, Fiber Bragg Grating interrogators and multipoint sensor chains for medical, industrial, structural, and OEM applications

By definition, a fiber optic sensor consists of the passive Sensor, active Signal Condition/Controller and the fiber optic link that connects them. The Controller is active, sourcing light to the Sensor and interrogating the return light signal according to its underlying optical principle. The Controller provides standard electrical interfaces that make the fiber optic aspect of the system transparent to the user’s control system. Hence, a FO absolute encoder outputs position via SSI or analog output, an incremental encoder outputs A/B quadrature signals or analog output for monitoring speed or relative position, an emergency stop provides relay contacts for control, and a temperature sensor system outputs digital values via USB in °F or °C units. Sensors are available based on either SM/MM Glass (GOF) or Polymer (POF) optical fiber link technology.

Some applications and the fiber optic sensor attributes which enable them:

• MEDICAL. Non-metallic MRI safe sensors enable fMRI functionality and medical device development. Applications include MRI cradle position, MRI phantoms, and MRI-guide biopsy and surgical robots.

• PHARMA & FOOD PROCESSING. FO temperature sensors are non-metallic and can operate inside microwave ovens and microwave reactors.

• ENERGY. Utility and energy applications require immunity to high voltage and all dialectric design. Fiber optic encoders can monitor tap changer position, switchgear state, generator and top drive speed. FO temperature sensors can measure hot spots in transformers, bus bars and switchgear. FO acceleration sensors can monitor transformer end winding stress and internal vibration.

• SEMICONDUCTOR. FO temperature and strain sensors can operation in high voltage plasma, microwave, RF and high magnetic fields.

• INDUSTRIAL. Industrial applications benefit from fiber’s interference feedback and inherent safety. A few examples include welding robots, smelters, mines, chemical plants and food processing.

• TRANSPORTATION. Electric railways, aerial trams, and aerospace benefit from the passive sensors’s electrical isolation and immunity to high voltage and lightning.

• MINING. Fiber optic position sensors provide inherent safety as well as can traverse the distances needed to monitor and control underground boring equipment and long conveyor systems.

• CIVIL. Multipoint FBG strain sensors can monitor strain, movement, and shifting in buildings, bridges, tunnels, composites, and other structures in advance of potential failure

• INFRASTRUCTURE. Fiber optic position sensors traverse the distances needed to monitor and control lift bridges, dams, floodgates, sluice gates, and hydroelectric plants

We are offering a 10% discount on GaAs temperature and multipoint FBG sensors for SC25 attendees. Mention promo code SC2025 for the 10% show discount, for orders placed through August 2025..

…And this is the BUZZ emanating from Micronor Sensors at Sensors Converge from Micronor Sensors.