FREY AG

Fiber Optic Rotary Encoder Withstands Lightning Strikes

Application Description:

In situations where human travel is necessary but where the geography is too steep or treacherous, aerial tramways often are used as a convenient alternative. Ski resorts, mountaineering centers, mining, logging, even archeological sites and cities with a diverse geography have tapped tramways as a method of transportation.

Aerial tramways can carry anywhere from a few to over 100 people. Lately the systems are also being seen as viable alternatives in overpopulated cities where geography or the urban landscape prohibits conventional transportation networks such as additional roads, subway lines, or trains. Aerial tramways are also used as an escape route at launch sites; pads 39A and 39B at Cape Canaveral are fitted with such systems.

Requirements:

The aerial trams offer a mix of harsh environments, from the outdoor encoder installations with direct exposure to weather and lightning, to the noisy electrical environment of the indoor motor, drive and control system. Critical requirements included:

- Immune to Lightning

- Fully Water Sealed

- Submersible

- Heavy Duty Construction to withstand handling in a heavy construction environment

- Output Signals are adaptable to each individual installation

Electrical noise is an ever present issue with conventional electronics-based incremental encoders, typically picked up along the long power/signal run from the encoder to A/B electrical quadrature inputs of the control system. This distance can sometimes run 100s to 1000s of feet. Electrical noise can add false pulses to the encoder’s output which would periodically defeat the fail-safe synchronization of the drive control system. A fiber optic sensor solution offering immunity to EMI and lightning inherently solves this problem.

Solution:

When FREY AG (Stans, Switzerland) began constructing new aerial tramway systems, it turned to Micronor’s fiber optic MR316 ZapFree® ruggedized high resolution shaft rotary encoder to be part of the tramway’s positioning and cable systems. Aerial tramways differ from gondola lifts, which have smaller cabins, carry lighter loads, have several “cars,” and rely on a circulating looped cable. A reciprocal aerial tramway is composed of one or two fixed track cables, a loop of cable called a haulage rope, and two passenger cabins (some have only one).

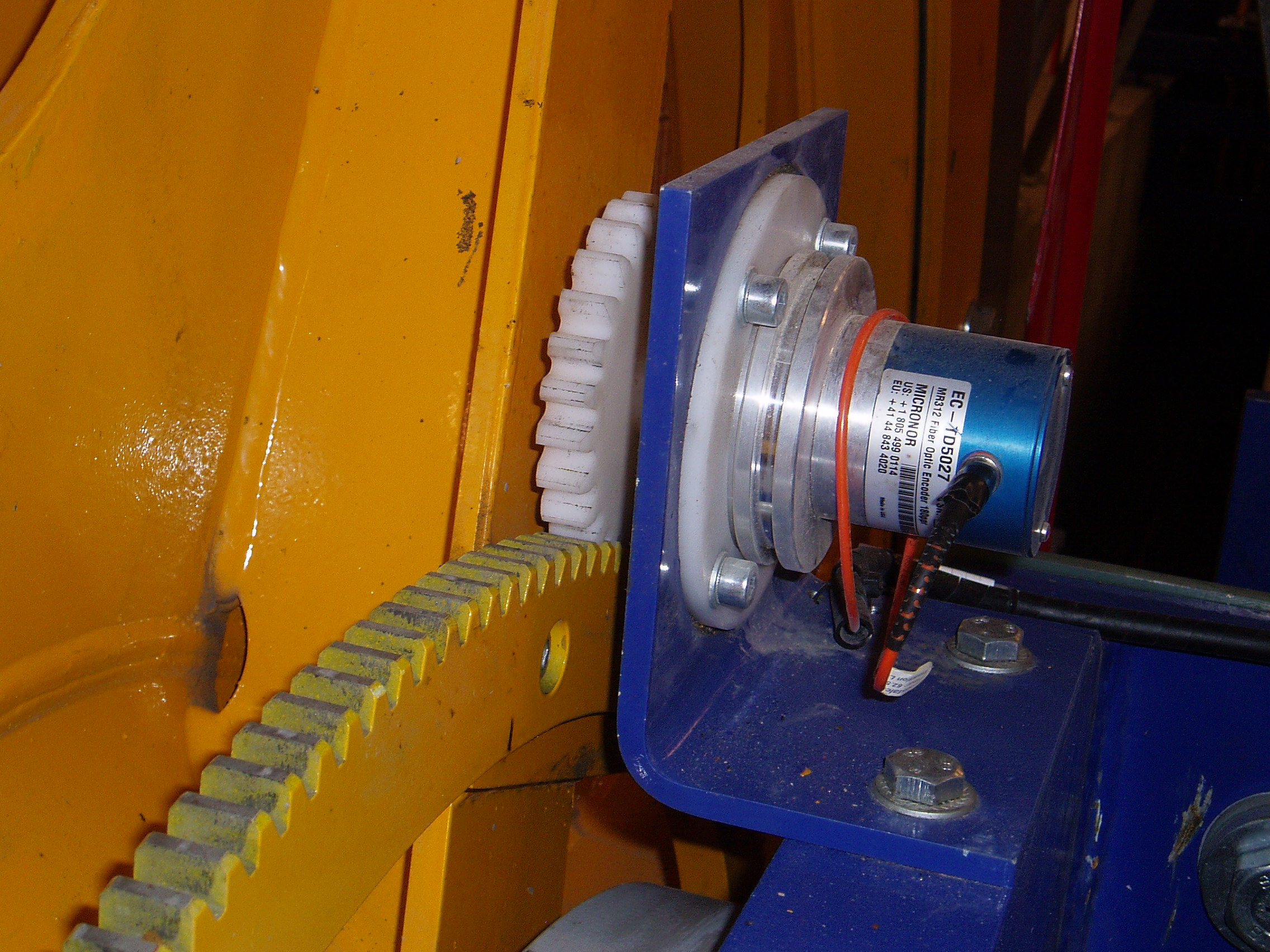

The fixed cables provide support for the cabins. The haulage rope is usually driven by an electric motor, and, being connected to the cabins, moves them along the span of the tramway. The entire system uses a “jig-back” system, where the weight of the down coming cabin helps to pull the other cabin upwards. The MR316 passive fiber optic rotary encoder is used by FREY AG as part of the aerial tramway’s complex safety system, and is immune to lightning and other atmospheric conditions that could potentially disrupt function. The encoder has no integral electronics whatsoever as all Micronor fiber optic sensors. Specifically, the encoder is used to determine both the position of the cabins on the system as well as sense any potential slippage of the cable.

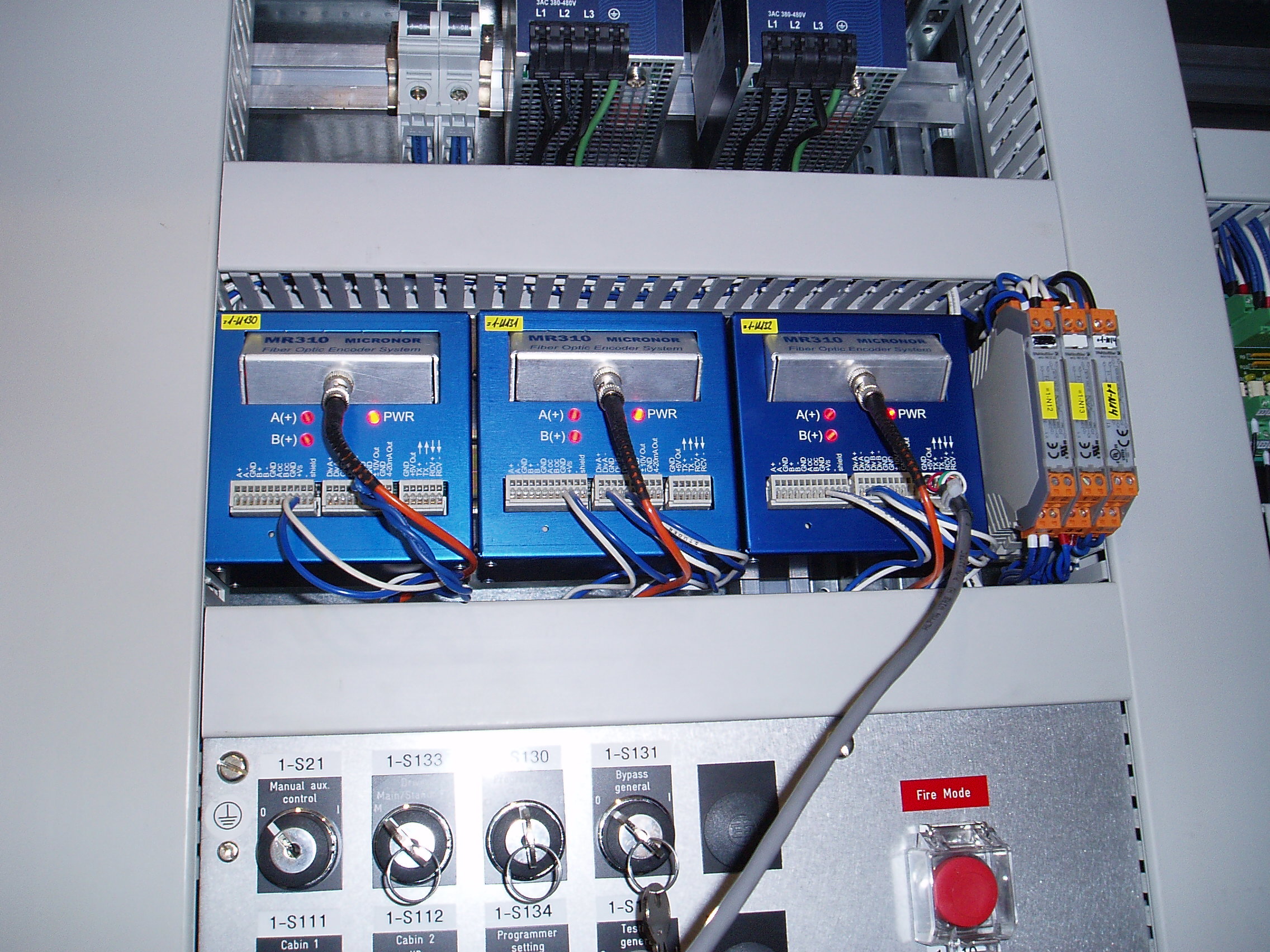

The safety-relevant monitoring systems, which in previous systems had been implemented in electronic boards and relay technology, are today implemented in programmable safety control systems Previous installations required an encoder, a pulse conditioner for Lightning Protection a frequency divider and a scalable frequency to voltage converter. The MICRONOR MR310 controller combines all the above function within on unit. Lightning protection is inherent to the fiber optic sensor and the frequency divider and scalable voltage output were already standard to the MR320 controller unit. As part of the installation package, Micronor provides ZAPPY™, a PC software program, which field technicians use to set the appropriate parameters for the given installation.

While Micronor designed the MR326 for environments where hazards to encoder function are obvious such as in heavy industry or EMI/RFI environments, FREY systems must also be immune to environmental factors such as corrosion, that are more surreptitious and long term. The company’s aerial tramways run in a wide range of geographical environments, from the moisture-laden conditions of the Colombian cloud forests, to the thin, cold air of the Swiss Alps, to the dry, hot air of Saudi Arabia’s western mountains, to the saline environment of South Africa’s coastal ranges. Each region presents a unique set of conditions for an encoder function that is exposed to the elements 24 hours a day and year-round. Several tramways also run in urban settings, whose man-made microenvironments present yet another set of conditions pertaining to operation. FREY does not restrict its use of the encoder to aerial tramways; the unit is also being used in the company’s inclined railway systems.

Implementation:

FREY AG aerial tramway installations are situated throughout the world. In the United States, Micronor had the unique opportunity to directly participate in one of those projects, the start-up of the $57-million Portland (Oregon, USA) Aerial Tram, which commenced operations in December 2006. The project was a joint venture between the City of Portland and Oregon Health Sciences University. The university needed a cohesive transportation solution to connect both upper and lower campus sites and the city saw the project as a tourist destination and means to lessen automobile traffic.

The 3,300-foot tram system ferries passengers (79 per cabin) in three minutes from downtown Portland’s South Waterfront District to the summit of Marquam Hill. The tram has succeeded as a popular tourist attraction, offering incredible views of the cityscape, the Columbia and Williamette Rivers which flow thorugh the city, the surrounding forests, and snow-capped Mt Hood in the distance. A symbol of success, the tram carried its one millionth passenger on October 17, 2007 and celebrated its ten millionth rider on January 8, 2014.

Micronor Part Numbers:

- MR316-C12T00 (EC-TD5027) Fiber Optic Incremental Encoder

- MR310 (EC-TD5245) Controller

- The original MR310 series fiber optic encoder system is now succeeded by the MR320 series, launched in 2011.

Numbers:

3300 Linear Travel of Portland Aerial Tram in feet

2007 Tram began operation in December 2007

256 PPR, Resolution of encoders used

3 MR316 encoders used by tram system