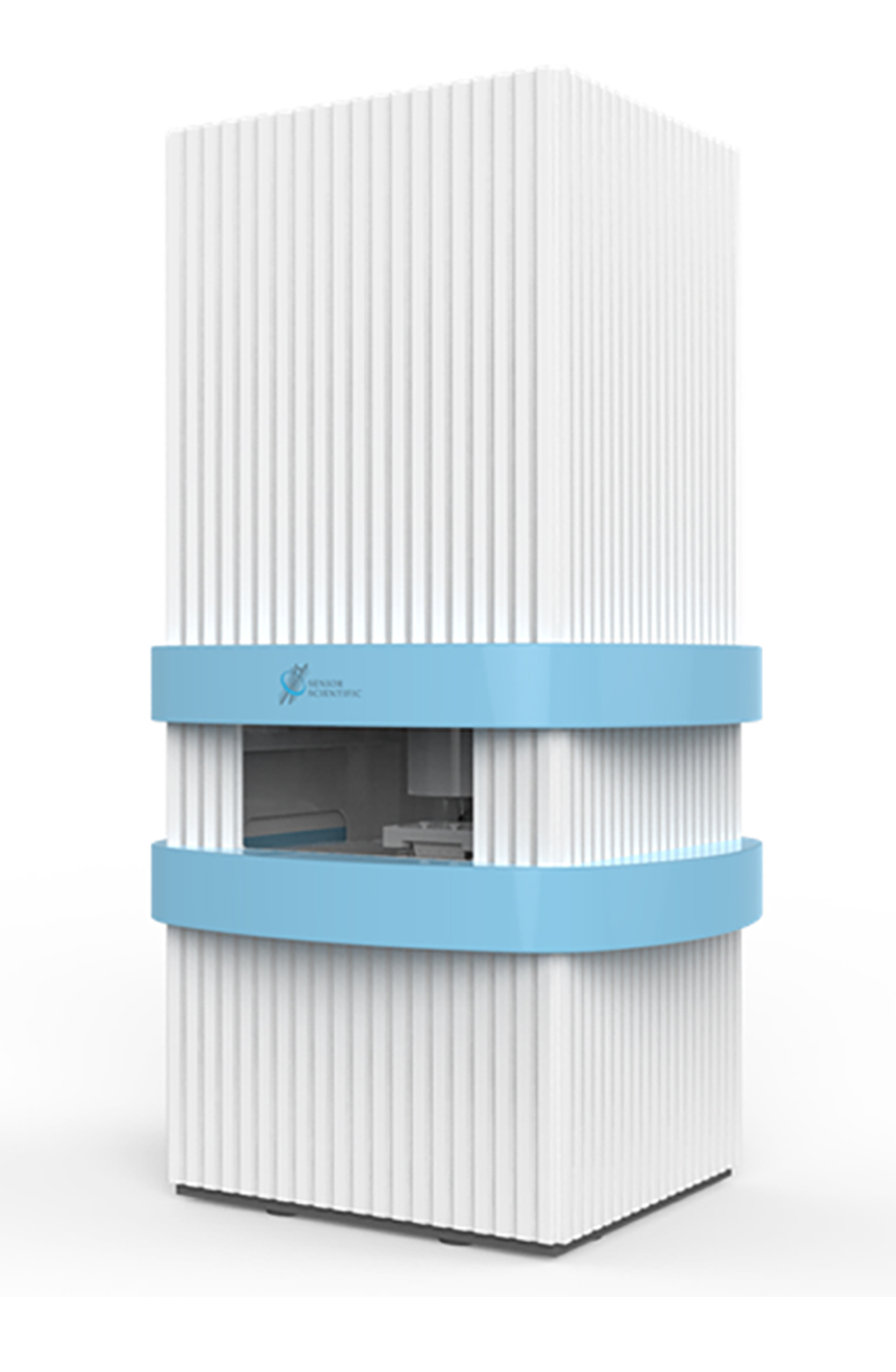

IMAGION BIOSYSTEMS, INC.

Fiber Optic Linear Encoders Guide Superparamagnetic SQUID Sensor

Application:

Imagion Biosystems, Inc. (Albuquerque, NM) is at the crossroads of biotechnology and nanotechnology. The company’s novel bioimaging and nanomagnetic detection systems have been developed specifically to detect cancer and other diseases earlier and with higher specificity than is currently possible. Tumor detection is accomplished by injecting a low dose of biologically-targeted nanoparticles (NPs), applying a brief magnetic pulse, and then detecting the resulting signal with an ultra-sensitive superconducting quantum interference device (SQUID). An advantage of superparamagnetic relaxometry (SPMR) compared to some imaging-based technologies is that it does not expose patients to potentially harmful ionizing radiation (e.g. x-rays) or radionuclides (e.g. PET) and is safe for human use.

Based on measurements of live cells of breast, ovarian, prostrate and leukemia cancers, they have been able to detect down to 10,000 cancer cells using the first generation MRX™ system. In comparison, transvaginal ultrasound (TUV) requires at least one billion ovarian cancer cells and breast x-ray mammography requires more than 100 million cells to detect the presence of breast cancer. The inherent sensitivity of SPMR holds great promise for enabling earlier cancer detection and lower medical costs.

Requirements:

The second generation Imagion Biosystems MRX™ instrument is designed to support both in vivo (live cells in live animal tissue) and in vitro (test tube or cultures) testing to further validate SPMR technology before moving to first in-human testing. In operation, a sample is placed on the specimen platform that has 3 DOF (degrees of freedom) with up to ±4 cm movement in the X and Y axes, and 0-20mm in Zs.

After injection and dispersal of the NPs, a small magnetizing field (50 Gauss) is applied for 0.75 seconds. Once the magnetic field is turned off, NP magnetic decay is measured (over 0.1 to 2 seconds) by the SQUID detector array. Additional measurements can be taken at different X and Y positions to form a topographic map of the magnetic dipoles, thereby identifying both size and location of tumors. The linear motion in the X and Y axes is driven by non-metallic, pneumatic actuator system but lacks complementary linear position feedback.

The MRX™ Sample Positioning System (SPS) required linear position sensors meeting these requirements:

- Entirely non-metallic (since the SPS will be within the magnetized field)

- 1mm resolution

- Immune to magnetic fields

- Invisible to magnetic fields (large and small)

- Not affect ultra-low level SQUID detection

Solution:

To monitor absolute linear position, pre-production prototypes of the MR303 MRI safe linear encoder and MR302-1 DIN rail mount controller were proposed and used. The first MRX™ unit assembled with the MR303 and MR302-1 components operated successfully and production parts were used thereafter to build additional instruments.

Implementation:

The photo shows one axis of the SPS motion system incorporating the pneumatic actuator and MR303 Linear Encoder. Each stage moves along a fixed encoder film strip. The linear sensor is connected via duplex fiber optic cable to the remote MR302-1 Controller which outputs A/B quadrature pulses for position tracking by the MRX™ control system.

Products Used Per System:

- MR303-B400C05 MRI Safe Linear Encoder, Qty 2

- MR302-1 DIN Rail Mount Controller, Qty 2

- EC-TD5334 series Encoder Film Strip, Qty 2

Numbers:

50 Magnetic field strength in Gauss

20 Samples move up to 20cm on Z axis

4 Samples move up to ±4 cm on X and Y axes

2 MRX™ Sample Position System features 2-axis positioning