FiSens® FBG Sensor Chains

FBG Sensor Chains for use with FiSpec Interrogators

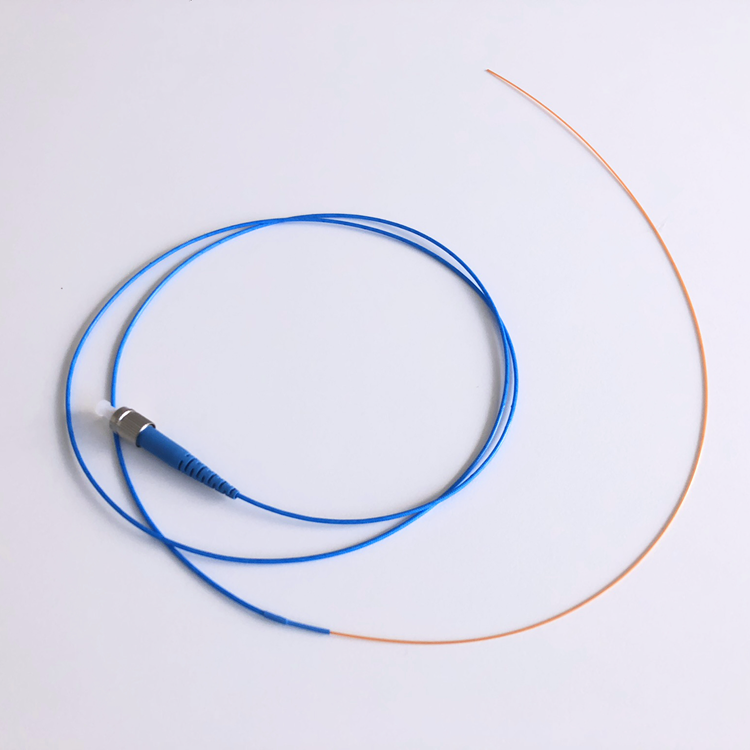

The FiSens® FBG Sensor Chain is a spliceless chain of multiple high-precision FBG sensors “written” into a single SM800 fiber. When the sensor is paired with a FiSens® interrogator offers a multipoint, distributed sensing solution for temperature or strain measurements. The FBG sensor chains utilize a unique fentosecond (fs-Laser) Laser Inscription method offering an innovative FBG-based solution with best performance together with lowest cost per sensor point on the market.

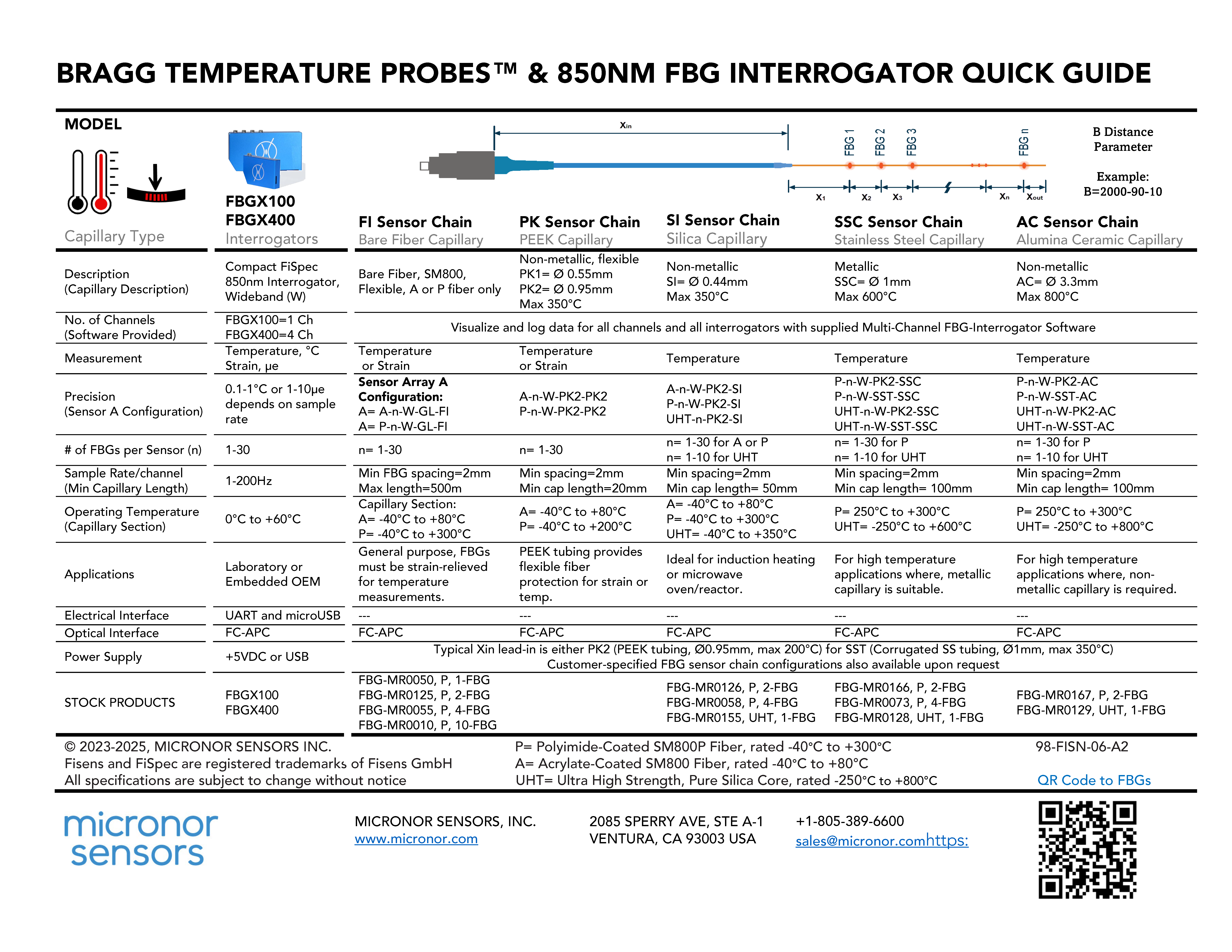

Specifications

The following is a summary specification of FiSens FBG Sensor Chains. Consult the individual data sheets and manual for detailed performance and interface information.

| Measurement Range | Max Temperature Range= -250°C to +800°C, but actual range depends on selected combination of Fiber, Jacketing and Capillary options chosen for sensor chain. Widest temperature range is usually restricted to the capillary section as the FO Connector and Lead-In are typically lesser rated. If each temperature point moves in the same direction, then max temperature measurement range is possible.Max Strain Range= ±40,000με for 1-FBG sensor chain. For multiple FBGs, strain range is a function of Fiber option, # of FBGs, spectral spacing, and direction of strain (positive or negative). If each strain point moves in the same direction, then max strain range is possible.

IMPORTANT NOTE: Actual measurement range – temperature and/or strain – depends on selected Fiber, Jacketing, Capillary and FBG-spacing as well as direction of measurement parameter (positive or negative). Contact Micronor Sensors sales for guidance if >300°C or >2000 με is required. |

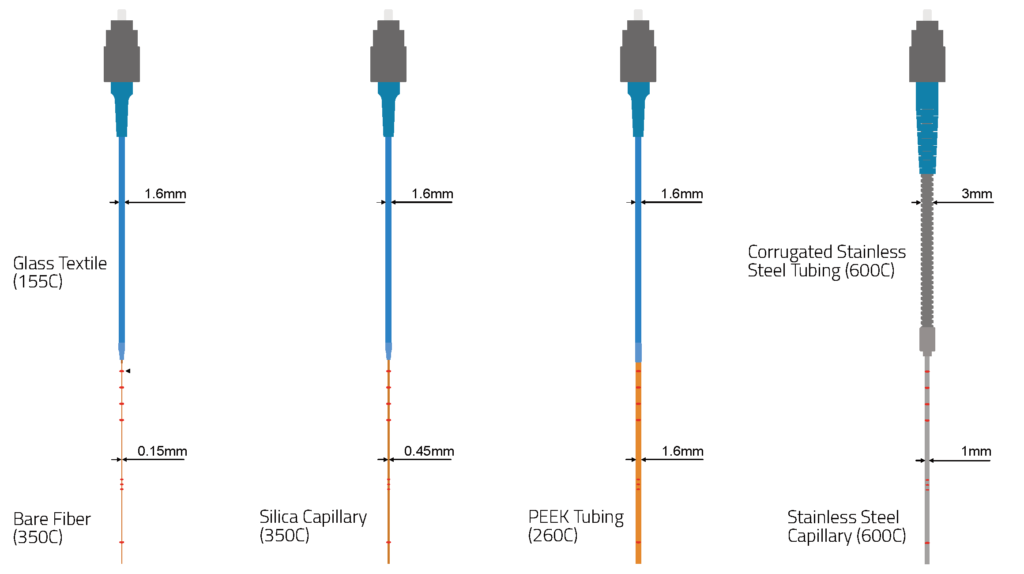

| Lead-in Jacketing Options | Glass textile sleeving (GL) or PEEK tubing (PK) or Stainless Steel Corrugated Tubing (SST) |

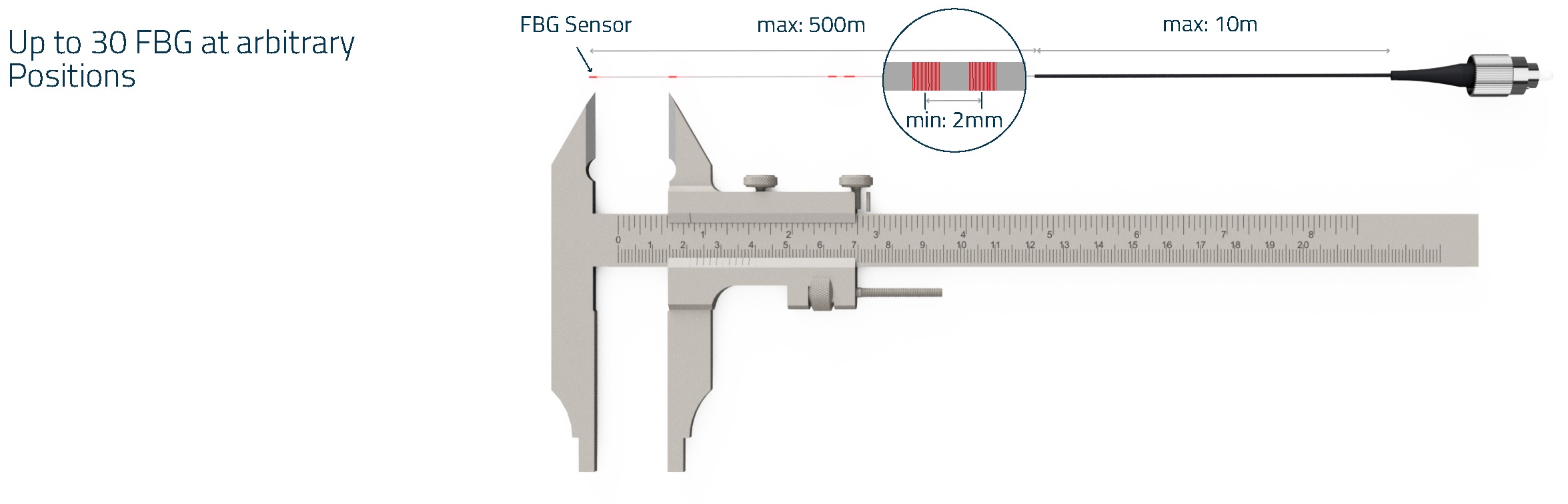

| Sensor Chain Length | Up to 500 meters |

| Number of FBGs | Up to 30 (per channel) with Wideband FBG100/FBG400 interrogator Up to 24 (per channel, total for all optical ports) with Narrow band FBGX1000 interrogator |

| Grating Length | approx 1mm |

| Grating Spacing | Minimum Xn space is 2mm (center to center), equivalent to 1mm spacing between FBGs |

| Fiber Types< | Standard=SM800 single-mode fiber, 5.6µm core, polyimide coated (max 300°C) UHS=Ulta High Strength, pure silica core, polyimide coated (max 300°C) UHT=Ulta High Temperature, pure silica core, no coating (max 800°C) |

| Bend Radius | Min 5mm for FI bare fiber capillary Min 40mm for PEEK tubing capillary (flexible and typically used where some protection of the FBG is required) Other capillary options are rigid or semi-rigid, for use as temperature sensors which require strain relief – Silica, Stainless Steel, and Alumina Ceramic |

| Fiber Optic Connector | FC-APC, rated -40°C to +85°C |

Specifications subject to change without notice

FiSens® is a registered trademark of FiSens GmbH

Features

- Up to 30 measurement points per fiber

- Sensor chains up to 500 meters

- Innovative and automated fs-Laser Inscription Method enables high precision FBG sensor chain manufacturing

- Temperature measurement precision to 0.1°C

- Strain measurement precision to 1µε

- Customizable FBG configurations

- Stable up to 350°C

Interfaces

- FC-APC, Standard Connection

- Sensor chains fabricated from industry-standard SM800 single-mode fiber

Software Support

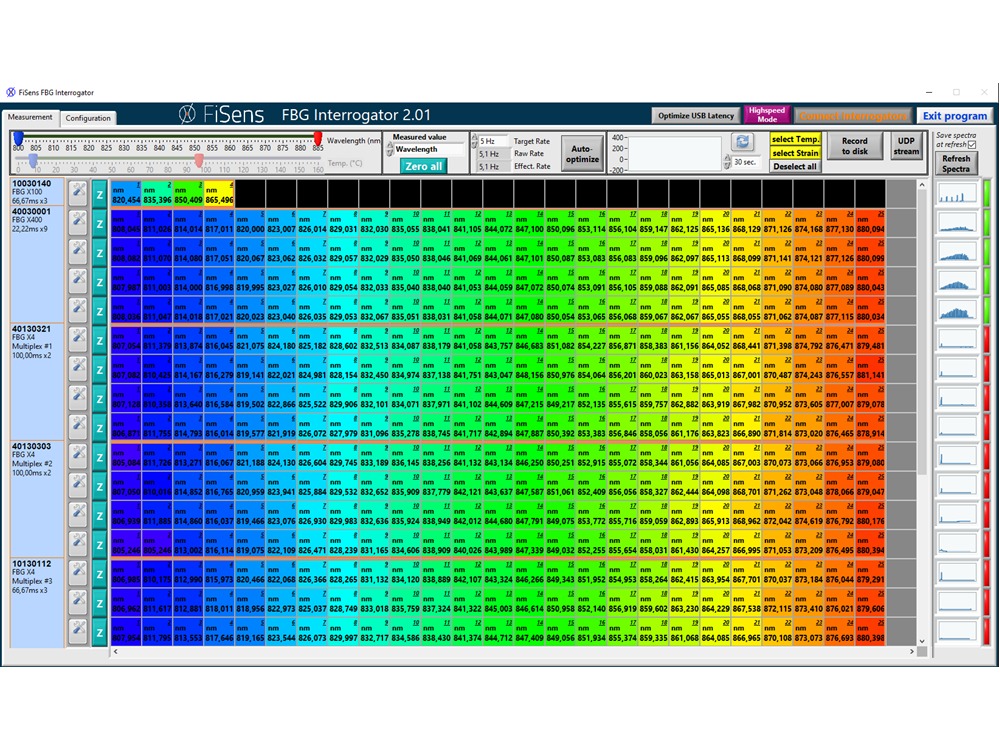

- FBG Sensors Chains are compatible with all FiSens® FBGX series Interrogators.

- General purpose BRAGGSENS and multichannel FBG-INTERROGATOR application software available at no charge. Supports data logging FBG data (wavelength, temperature, and strain) in Excel compatible format. Based on National Instruments LabView® runtime kernel.

- Programmer/Software manual provides support for embedding FBGX communications into customer-developed software.

- Contact Sales for overall technical support.

Downloads

FiSens FBG Sensor Chain Configurator Datasheet

FiSens BRAGGSENS (Single Channel) Software Quick Start Guide

FiSens FBG-INTERRROGATOR (Multichannel) Software Quick Start Guide

FBG-MR0010 10-FBG Sensor Chain Drawing

FBG-MR0050 1-FBG Sensor Chain Drawing

Quick Ship Configurations

| FBGX100 | Standard 1-Channel Interrogator, max 30 FBGs |

| FBGX400 | Standard 4-Channel Interrogator, each FBG Sensor Chain can have max 30 FBGs (total of 120 for 4 channels) |

| FBG-MR0150 | STOCK 1-FBG Bare Fiber Sensor Chain, A=P-1-N-GL-FI, B=1000-200-10, |

| FBG-MR0055 | STOCK 4-FBG Bare Fiber Sensor Chain, A=P-4-W-GL-FI, B=2000-35-10-10-10-10 (FBGs are 10mm apart) |

| FBG-MR0058 | STOCK 4-FBG Silica Capillary Sensor Chain, A=P-4-W-GL-SI, B=2000-35-10-10-10-10 (FBGs are 10mm apart). Ideal for Temperature Measurements, -250°C to +300°C. |

| FBG-MR0073 | STOCK 4-FBG All Stainless Steel Sensor Chain, A=P-4-W-SST-SSC, B=2000-35-10-10-10-10 (FBGs are 10mm apart). Ideal for Temperature Measurements, -250°C to +300°C. |

| FBG-MR0010 | STOCK 10-FBG Bare Fiber Sensor Chain, A=P-10-W-GL-FI, B=1000-(10*100)-100 (FBGs are spaced 100mm apart) |

TO ORDER

Call +1-805-389-6600 or email sales@micronor.com

Ordering Information

Every FBG sensor application and sensor configuration is different. Micronor specializea in providing the unique configuration that your application requires. Typical lead time is 3-4 Weeks ARO for small quantities. An Ordering Part Number can be assigned and quoted within 1-2 business days.

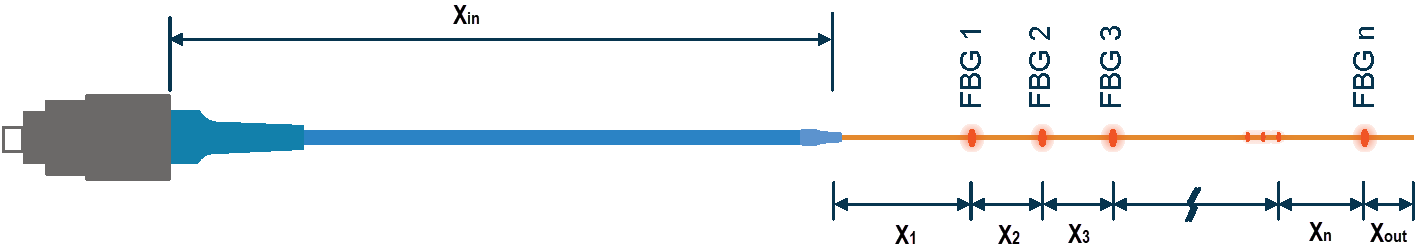

Sample FBG configuration (same as stock sensor chain FBG-MR0055): A=P-4-W-GL-FI, B=2000-35-10-10-10-10

Description: General Purpose FBG Sensor Chain for Temperature or Strain sensing with 4 FBGs for use with Wideband Interrogator, Glass Textile (GL) with Bare Fiber FBG sensor capillary (FI), Xin=2000mm (2m, length of GL Lead-in),FBG1 to be 35mm (X1) from end of Lead-In, FBG1-FBG4 are spaced 10mm apart (center to center), Xout length=10mm

| Sensor Type | Options: P=Polyimide-coated SM800P fiber (Standard), for Temperature or Strain measurements (-40°C to 300°C) A=Acrylate-coated SM800P fiber, for limited range Temperature measurements (-40°C to +80°C) UHS=Ultra High Strength, for strain measurements in extreme temperatures (-250°C to +300°C) UHT=Ultra High Temperature, for extreme temperature measurements (-250°C to +800°C) |

| FBG Quantity | 1 = 1 FBG, up to maximum 30 = 30 FBGs |

| Spectral Range |

W = Wide band (808-880nm, max 30 FBGs per sensor chain per channel). For use with general purpose FBGX100/FBGX400 interrogators only. N = Narrow band (808-865nm), limited to max 24 FBGs total. For use with either general purpose FBGX100/FBGX400 or high speed/high precision FBGX1000 series (single channel, multiple optical ports) |

| Lead-In Protection/Jacketing Type |

For Standard applications, GL = Glass Textile (max 155°C). |

| Sensor Capillary | FI = Bare polyimided-coated fiber PE = PEEK Tubing (max 260°C) SSC = Stainless Steel Capillary (max 600°C) SI = Silica capillary (max 350°C) AC = Alumina Ceramic capillary (max 800°C) |

| Xin | Length of Lead-in in mm, Options 50-10’000 mm |

| X1..X30 | Specify distance from previous FBGn-1 to next FBGn, in mm X1 = Distance from end of Lead-In to FBG1 X2 = Distance from FBG1 to FBG2, Minimum 2mm (length of 1mm FBG plus 1mm spacing) X3 = Distance from FBG2 to FBG3, Minimum 2mm etc. |

| Xout | Length of Lead-out termination in mm, 2-100mm |