Specifications

| Temperature range | -40 °C to + 140 °C (Nomex) |

| Material | Nomex or PEEK, depending on model |

| Conductivity | Non-conductive |

| Dimensions | See data sheets/drawings for information |

| Connector type | ST |

| Compatible Probes | SmartSpacer and SmarDisc to be used with TST2 transformer-series , fiber optic temperature probes. SmartBusvbar to be used with TS3 series fiber optic temperature probes. |

Ordering Information

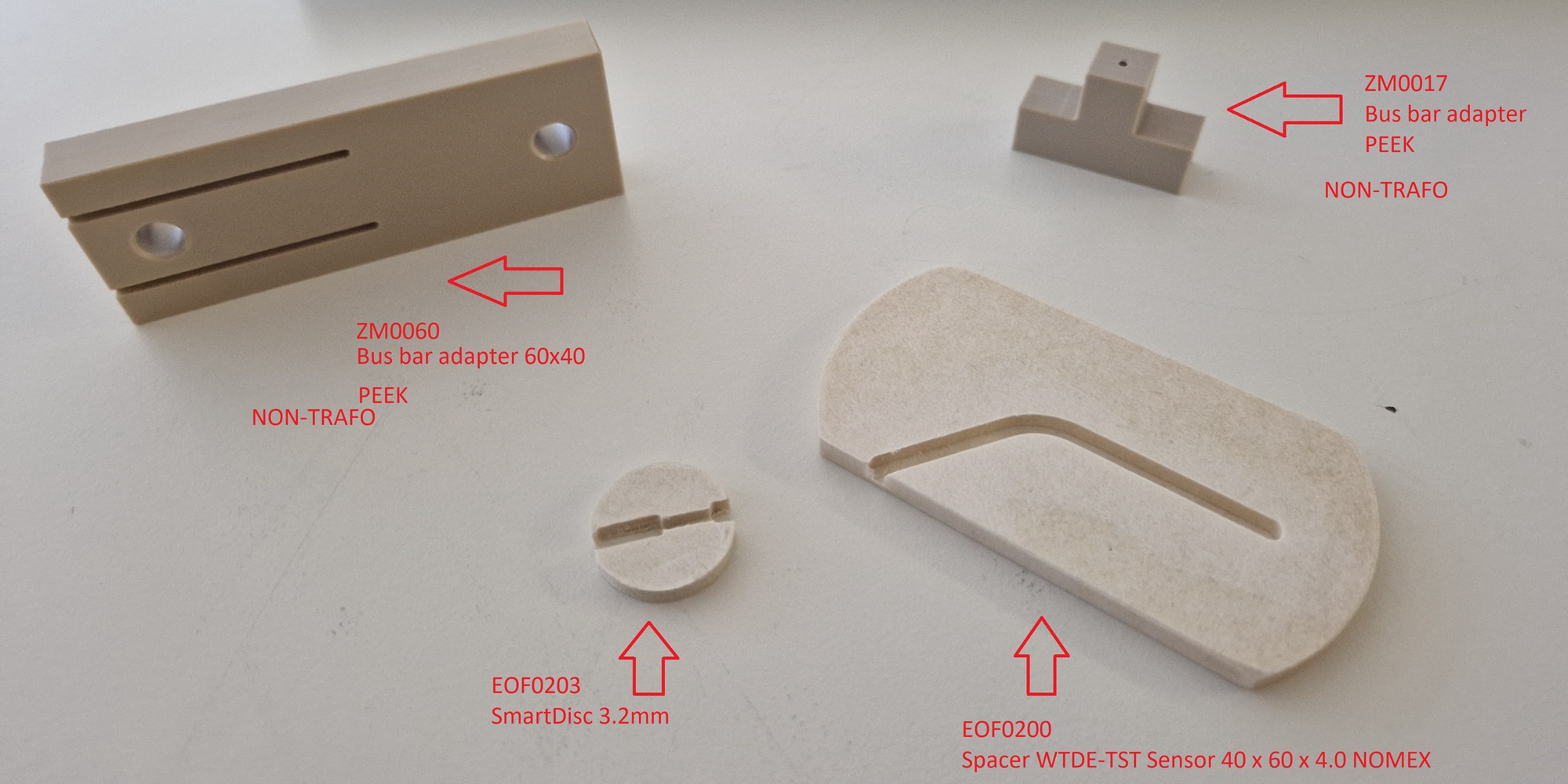

| EOF0200 | SmartSpacer for mounting TST2 temperature probe in transformer winding, Nomex |

| EOF0203 | SmartDisc for mounting TST2 temperature probe in transformer winding, Nomex |

| ZM0060 | SmartBusbar for radial mounting up to two TS3 temperature probe on high voltage busbar, PEEK |

| ZM0017 | SmartBusbar for axial mounting TS3 temperature probe on high voltage busbar, PEEK |

SmartSpacer, SmartDisc, and SmartBusbar mounting accessories

Why use TST Probes and SmartSpacer/SmartDisc for Transformer Monitoring?

Governed by the IEEE/ANSI or the IEC Loading Guide, the transformer upper loading limit, for normal or emergency operation, is set by the winding hot spot and/or top oil temperature. The upper loading limit may also be defined as a function of the allowed percentage loss of insulation life per operating cycle. Users of power transformers therefore want to understand the actual operating temperatures as a function of load applied to the unit in real time as a way of maximizing the asset value in use and minimizing the risk of overheating, excessive loss of insulation life, and/or failure. The system is designed to monitor and acquire key operating temperatures of the apparatus.

The data can be used to control the apparatus cooling systems and unit loading levels. TST2 probes and SmartSpacer products can be used at all voltage classes thorugh EHV and UHV levels. The COMEM Optocon real time FOTEMP-OEM (max 4 channels per module), FOTEMP-T20 (max 16 channels) or advanced FOTEMP-T30 (max 16 channels) monitoring systems can be connected to the operator’s local computer network or SCADA system to provide necessary thermal management data to the load dispatch center.

Why use TS3 Probes and SmartBusbar accessores for HV Busbar Monitoring?

Busbar temperature monitoring is important because it allows utilities, operators and end users to identify and correct problems as early as possible. By monitoring busbars, operators are able to detect problems such as overheating, corrosion, or degraded insulation. Monitoring is important to ensure that the energy distribution system is operating at its optimum. A properly functioning busbar system will reduce the load on the transformer and hence extend its life. Additionally, a busbar system can help in detecting anomalies early, so that they can be corrected before they lead to power outages.

The COMEM Optocon SmartBusbar accessories allow convenient mounting of TS3 temperature probes to provide safe contact with the surface of a busbar. Both the TS fiber optic temperature probes and mounting spacers are passive and non-conductive. Two standard SmartBusbar accessories provide for either axial or radial mounting of the TS3 probe and can withstand busbar temperatures to +180C.

Contact Micronor Sensors sales if you need a custom Smart mounting accessories for your High Voltage/High Temperature Monitoring Application

Features

- Non-conductive, PEEK or Nomex

- SmartSpacer and SmartDisc for mounting TST probes in transformer windings

- SmartBusbar for mounting TS3 probes on busbars and other switchgear

- Contact Micronor Sensors sales for customer mounting applications

TO ORDER

Call +1-805-389-6600 or email sales@micronor.com

Related Products