A Multipoint Distributed Sensor System

Micronor Sensors offer an innovative Fiber Bragg Grating (FBG) system that finally makes multipoint sensing for temperature and strain affordable compared to other distributed and discrete sensing solutions.

FBG sensors enable distributed sensing for critical asset monitoring in infrastructure, utilities, renewable energy, automotive, and industrial sectors to increase safety, enable smarter asset management, and reduce maintenance costs.

The sensors are rugged, miniature, and immune to RF and electromagnetic fields and high voltage, providing reliable measurements in harsh environments.

FBG System Components

FBG Sensor System = Sensor Chain + Interrogator

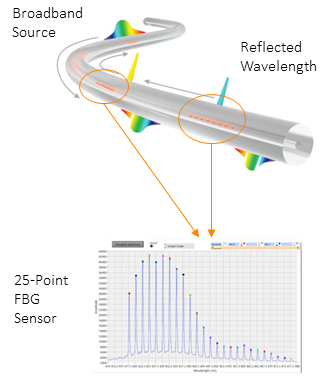

The system includes a readout device called the Interrogator and an FBG Sensor Chain, a single optical fiber with multiple temperature and strain FBG sensors. The sensor chain can consists of up to 30 FBG sensors per fiber over a maximum length of 500 m.

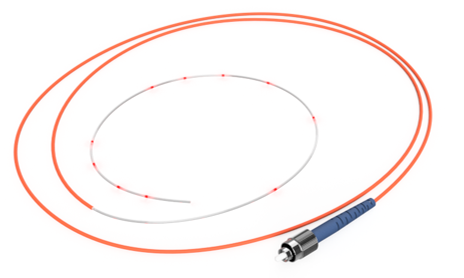

FBG Sensor Chain

Rugged and flexible FBG sensor chains for multipoint sensing.

Go to FBG Sensor Chain product page.

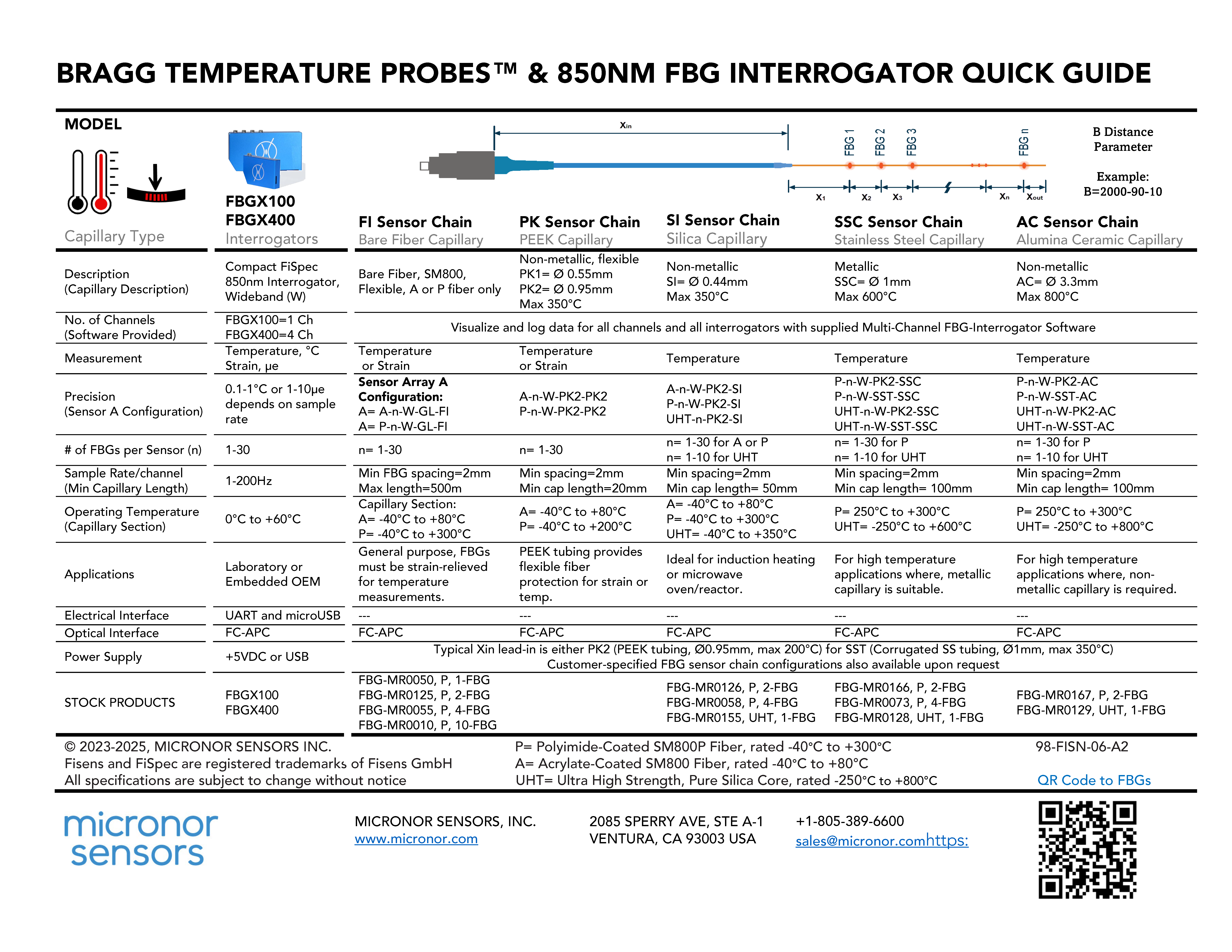

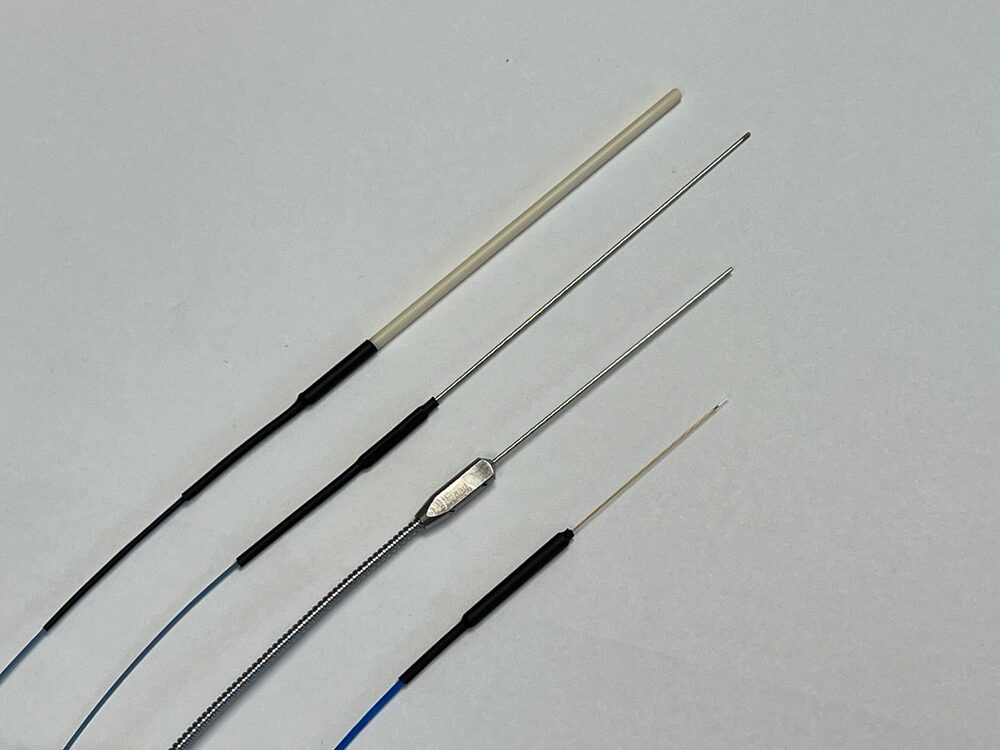

BRAGG Temperature Probes™

These are off-the-shelf FBG-based Temperature Probes for full range of applications. Capillary options are Silica, Stainless Steel or Alumina Ceramic. Depending on configuration, probes can measure up to a range of -250C to +800C. Accuracy is typically 1-3 degrees depending on specific range of measurement.

Go to BRAGG Tmperature Probes product page.

FBG Interrogator

High resolution, fast, compact, and fully integrated FBG interrogator.

Go to FBG Interrogator product page.

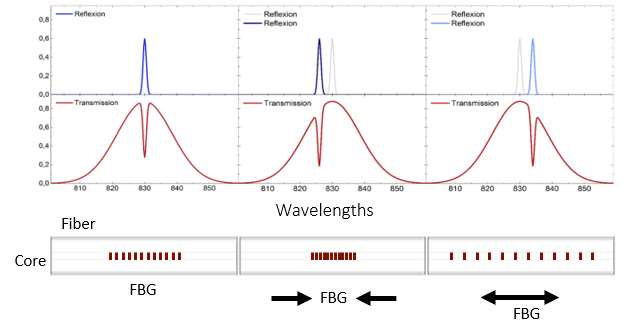

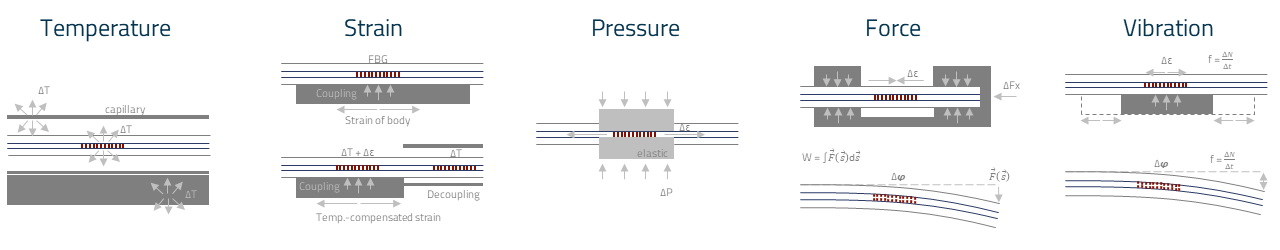

A Fiber Bragg Grating (FBG) is a microstructure written within the core of an optical fiber comprising a periodic modulation of the refractive index of the underlying glass material. When broadband light hits the periodic microstructure, one specific wavelength band is reflected, and all other wavelengths are transmitted.

The period modulation that is inscribed into the glass of each FBG like a spectral fingerprint defines the specific wavelength band that it reflects. If an external force or change in temperature is applied to the microstructure, the periodic modulation of the FBG will change slightly, causing the wavelength band that the FBG reflects to shift.

When the FBG sensor is exposed to strain or temperature, the reflected wavelength shifts:

- When the FBG is compressed (strain), the wavelength decreases

- When the FBG is stretched (strain), the wavelength increases

- When the temperature changes, the FBG deforms and refractive index changes, both of which cause the reflected wavelength band to increase or decrease

Applications

Effectively use the FBG system in applications that require:

- Comprehensive measurement of “heat or strain maps”

- Harsh environments – RF, electromagnetic fields, high voltages

- Long measurement distances

Why FBGs?

Fiber optic solution

- Inherently safe

- Immune to EMI and RFI

- Immune to RF, electromagnetic fields, and high voltage

- Reliable in extreme temperatures

Multipoint measurements

- Up to 30 sensors per sensor chain

- Measure distances up to 500 meters

- Measure both strain and temperature on one fiber

- Reduces wire complexity

Small form factor

- Small fiber diameter

- Flexible with 5mm bend radius

- Easy to install in constricted spaces

Cost effective solution

- Lowest cost per measurement point with 4 or more sensors

- Lowest cost of any FBG/interrogator system